High Quality 3-Phase Converters Since 1986.

Power your business with a Smith Electric Motorworks 3-Phase Converter. Regardless of your industry, we offer budget friendly converters to power the equipment that you rely on.

High Quality 3-Phase Converters Since 1986.

Power your business with a Smith Electric Motorworks 3-Phase Converter. Regardless of your industry, we offer budget friendly converters to power the equipment that you rely on.

High Quality 3-Phase Converters Since 1986.

Power your business with a Smith Electric Motorworks 3-Phase Converter. Regardless of your industry, we offer budget friendly converters to power the equipment that you rely on.

High Quality 3-Phase Converters Since 1986.

Power your business with a Smith Electric Motorworks 3-Phase Converter. Regardless of your industry, we offer budget friendly converters to power the equipment that you rely on.

High Quality 3-Phase Converters Since 1986.

Power your business with a Smith Electric Motorworks 3-Phase Converter. Regardless of your industry, we offer budget friendly converters to power the equipment that you rely on.

High Quality 3-Phase Converters Since 1986.

Power your business with a Smith Electric Motorworks 3-Phase Converter. Regardless of your industry, we offer budget friendly converters to power the equipment that you rely on.

We have been building phase converters for small and enterprise level business operations for over 30 years.

Whether you are starting a great enterprise or expanding the horizons of your hobby shop, welcome to our family of smart, satisfied users who are energizing their dreams with our 3-phase power.

Have questions? Customer service is our top priority at Smith. Regardless of your experience with 3-phase power, we are here to answer any questions that you may have and to help you out from the decision making process to technical assistance needs that you may have after making a purchase.

Big Business or Small Business, we have a converter to meet your needs

Static Converters

For equipment that may operate unattended, such as HVAC, refrigeration, water wells, irrigation, sewage lift stations, elevators and more.

Learn More →

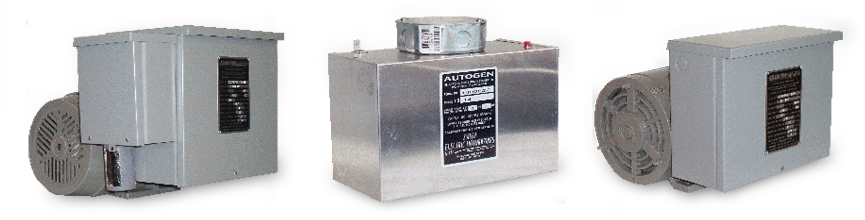

Rotary Converters

Our high efficiency rotary phase converters are available for rain- & dust-tight outdoor applications as well as quietly running and clean indoor applications.

Learn More →

DIGI Converters

Our DIGI Series converters are perfect for CNC, EDM, Computers, Lasers, and other voltage sensitive machine tools and equipment.

Learn More →

Rotomax Converters

Rotomax are cast iron totally enclosed rotary converters. Protected from the elements, they are perfect for agricultural and outdoor applications.

Learn More →

Special Converters

Our special converters can operate on a 24-hour basis without overheating due to our exclusive low-resistance rotor design. With automatic controls, these converters operate equipment with fixed or variable (multi-motor) loads that may start without warning.

Learn More →

Accessories

We offer accessories such as Kilogen Modules for managing current and balance on large or multiple load motors, Hand Start Panels to improve performance on any phase converter, and Line-Tamer soft starting options for utility compliance when necessary.

Learn More →

Have any Questions?

Download Our Product & Purchase Guide.

At Smith Electric Motorworks, we recognize that our all of our customers have different levels of experience and knowledge with phase converters. Our support staff is available to answer any questions that you have during the selection process and to offer technical assistance after you've made a purchase.

Smith Electric has the best Service and Support in the Converter Business!

Customer

Agricultural Industry

Best converters in the business!

Customer

Small Business Owner

Join Our Newsletter

Sign up to our newsletter to stay up to date with all the latest news, deals, and events.